What is EMC / EMI Testing?

An EMI/EMC test is a vital step when bringing a new product to market. Generally speaking, we can categorise this sort of test into two different categories: immunity testing and emissions testing.

Immunity testing measures the reaction of the device when it is being exposed to disturbances like electromagnetic noise. The aim of these tests to get a reasonable assurance that the device will perform as it is meant to when it is utilised within the expected operating environment.

Next, we have emissions testing, which will measure the amount of electromagnetic noise that is generated by a device throughout normal operation. The aim of these sort of tests is to make certain that any type of emission from the device is beneath the relevant limits that are defined for that device type. This, in turn, will ensure that there is a reasonable assurance that a device is not going to cause any damaging interference with other devices that operate within the expected operating environment.

Due diligence and regulatory compliance require electronic devices to undergo at least one of the two types of testing mentioned above.

What is the difference between EMI and EMC testing?

The terms EMC and EMI tend to be used interchangeably when referring to electronic component testing and the regulatory assessment of consumer goods. Because of this, a lot of people tend to assume that they are two terms referring to the same thing. However, that’s not the case. There are some clear differences, and it is important to be aware of them.

EMI can be defined as electromagnetic energy, which impacts the functioning of an electronic device. This is not the same as EMC, which measures the ability of a device to operate as intended within the shared operating environment, while, at the same time, not having an effect on how additional equipment operates within the same environment.

Let’s take a look at both in more detail below:

Electromagnetic Interference (EMI)

As mentioned, EMI is electromagnetic energy that impacts the functioning of an electronic device. Sources of EMI can often be environmental events that occur naturally, for example, solar radiation and electrical storms. However, in most cases, the source of EMI is another electrical system or electronic device. While you can generate EMI from any sort of electronic device, component, or equipment, such as LED screens, motors, welders, and cellphones, yet some are more likely to result in disturbances than others.

Because it is not typical for electronics to be in operation in isolation, products are typically engineered so that they can function with some degree of EMI being present. This is especially critical when it comes to avionics equipment, as well as products that demand enhanced reliability in all types of situations.

Electromagnetic Compatibility (EMC)

Now that you have a full understanding of EMI, let’s take a look at EMC in further detail. EMC is the measurement of how a device is able to operate as it is intended in a shared operating environment while making sure that other types of equipment are not impacted in terms of their intended use and operation.

Assessing how a device is going to react when there is electromagnetic energy exposure is one element of this. This is known as susceptibility or immunity testing, which we explained earlier in the post. Measuring the amount of EMI that is generated by the internal electrical systems device, i.e. emissions testing, is the other part of the process.

Both of the elements of EMC are critical engineering and design considerations in any system. If you do not anticipate the EMC of a device correctly, it can cause a number of detrimental consequences, including data loss, product failure, and safety risks. As a consequence of this, there are many different types of EMI and EMC testing tools and equipment that have been developed so that engineers have the full picture when it comes to the operation of a device within real-world conditions.

Why EMI/EMC testing is required?

EMC and EMI tests are required to make sure that electrical goods are safe for consumer use and that they adhere to the current regulations that are in place. The likes of satellite TV dishes, laptops, cellular phones, microwave ovens, and other consumer goods need to undergo EMI and EMC testing to make sure that harmful interference is not caused by these products. The tests will also ensure that the devices are able to accept interference without causing any undesired operation while in real-world conditions.

Overall, EMI and EMC testing are critical because they ensure that consumer products are safe and that they work within their intended purpose. There are a number of common issues that designers and engineers face during the production process, including over powerful electronic emissions and thermal problems. These emissions can then interfere with other devices, causing further problems. This is why it is imperative that you test products extensively throughout every step of the product development process to ensure that the item is deemed safe and that it can be moved to the next stage within the production process. Planning for tests like this is key in product development.

Is EMI/EMC testing safe? How to test EMI and EMC?

You may be wondering what to expect from an EMI and EMC test. The specific testing routine is going to be determined by the nature of the device in question, as well as the regulatory requirements governing its use and the intended application. Therefore, the way in which an EMI test is carried out on one device is not going to be the same as another device.

The electromagnetic phenomena that EMC testing may stimulate include the following:

• Quick transients that are caused by the likes of fluorescent lamp ballasts, relays, motors, and electrical switches.

• Electrostatic discharges that are linked with static electricity.

• Radiated and conducted electromagnetic noise.

• Electromagnetic surges that are a result of a lightning strike.

• Voltage drops that have happened because of a power interruption, such as a brownout.

• Magnetic fields, such as those that radiate from electrical wires.

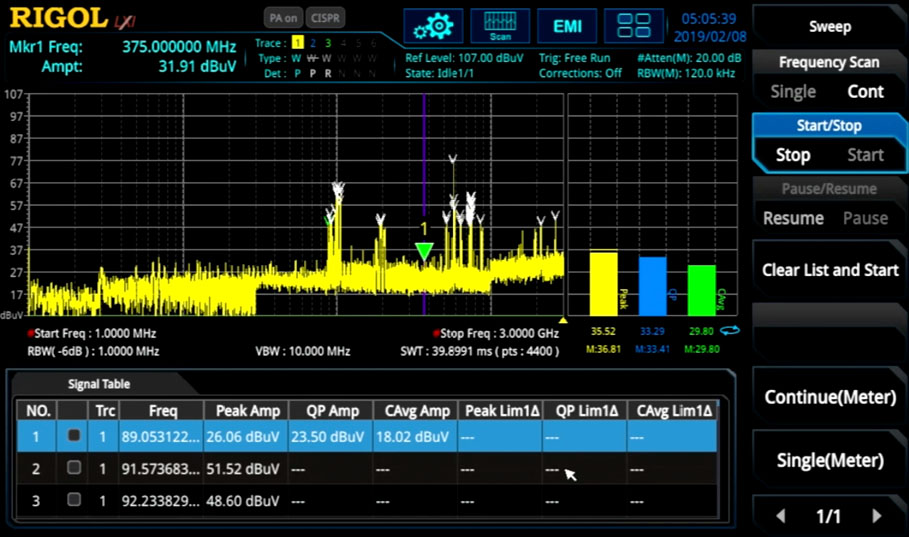

A broad assortment of equipment is utilized so that the above conditions are stimulated and the ability of the device to recover from them is determined. The likes of equipment that may be used during a typical EMC test include spectrum analyzers, power amplifiers, and surge generators.

In terms of testing, EMI and EMC testing are safe, so long as they are carried out by licensed and experienced professionals and are in accordance with the regulatory guidelines that are in place.

There are a number of different standards in place, and the ones that you need to adhere to depends on the product in question and the part of the world you are based in.

Aside from this, you have the FCC Part 15 rules, which are vital because they define the limits for the amount of unlicensed radio frequency interference that consumer electronics and other devices can produce.

Outside of the United States, there are a number of different standards, including CISPR, IEC, and ISO standards, which will define the acceptable limits of overall EMC and EMI. In some markets and industries, compliance with these standards is on a voluntary basis. However, there are many industries whereby compliance is a requirement and you can find yourself in heaps of trouble if you do undergo this critical testing.

Final words on EMC and EMI testing

So there you have it: an insight into EMI and EMC testing. We hope that this has helped to give you a better understanding of what to expect when it comes to having an EMI and EMC test carried out on a product that you intend to bring to market. This is a critical part of the process, which is essential in ensuring that your electrical devices function as they should within the specific environment.